Overview

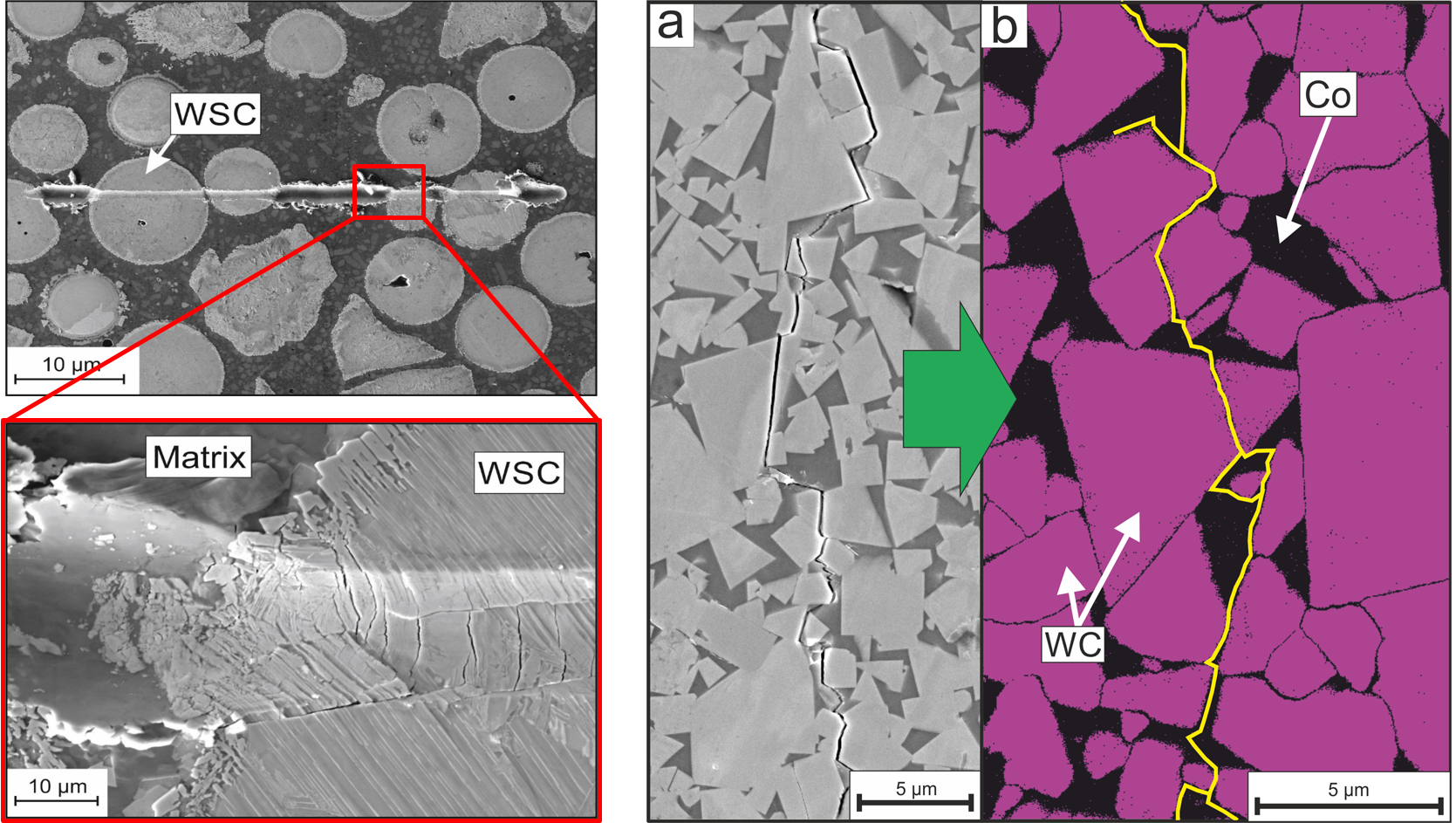

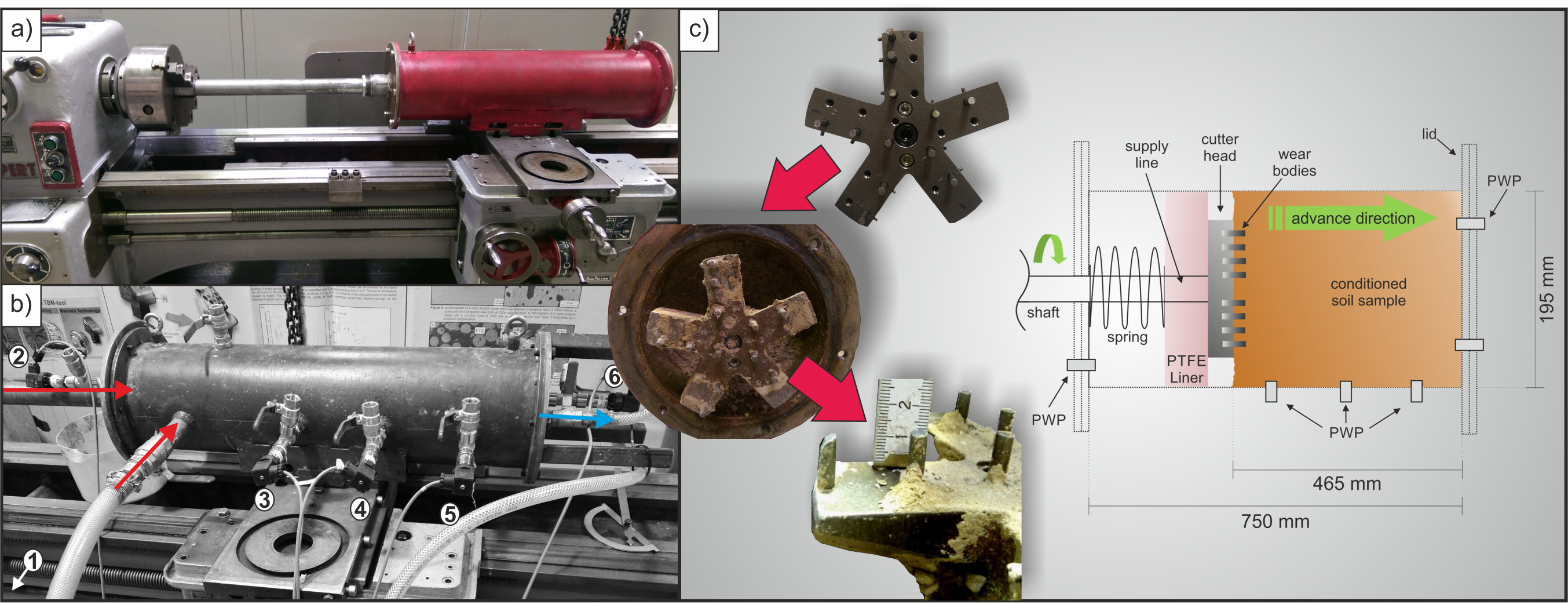

Wear and the associated service life of tools are counteracting the efficiency of tunneling processes. Till today an insufficient knowledge about the acting wear mechanisms and the interactions between the ground to be excavated and the tunneling tools are given. Based on this circumstance, no reliably predictions about the wear condition and the remaining service time of tunneling tools can be obtained. It is the aim of C5 to describe the complex tribological system of tunneling tools in soil and soft rock. In addition, tool-ground interaction is being thoroughly investigated so that crack initiation, crack propagation and ultimately ground degradation can be fundamentally understood. Thus, in subproject C5, geophysical investigations of rock-fragmentation and examinations of the tool wear from a materials technology perspective will go hand in hand, so that the entire tribosystem can be considered and understand comprehensively and interdisciplinary. Furthermore, subproject C5 intensively interacts with the subprojects C4 and C6. Thereby, C4 and C6 are focusing on numerical methods and questions with respect to fragmentation of the ground and the wear of the tools. Subproject C5 will support both numerical projects by providing input data as well as by validating the calculations by experimental tests.