Overview

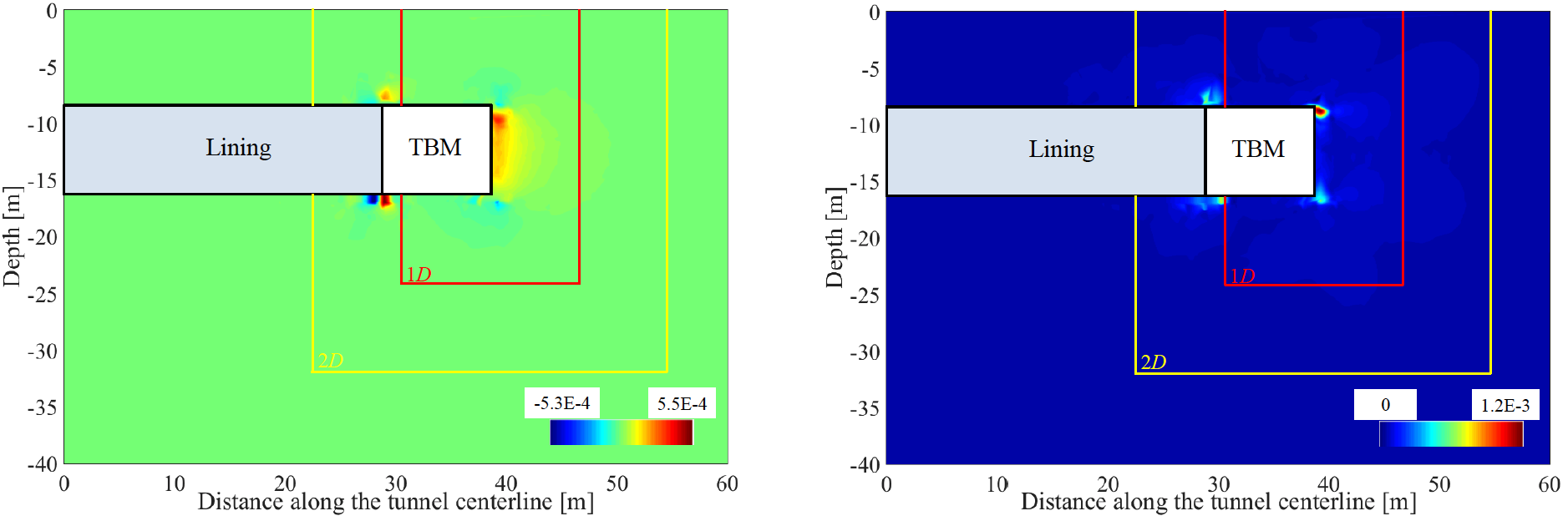

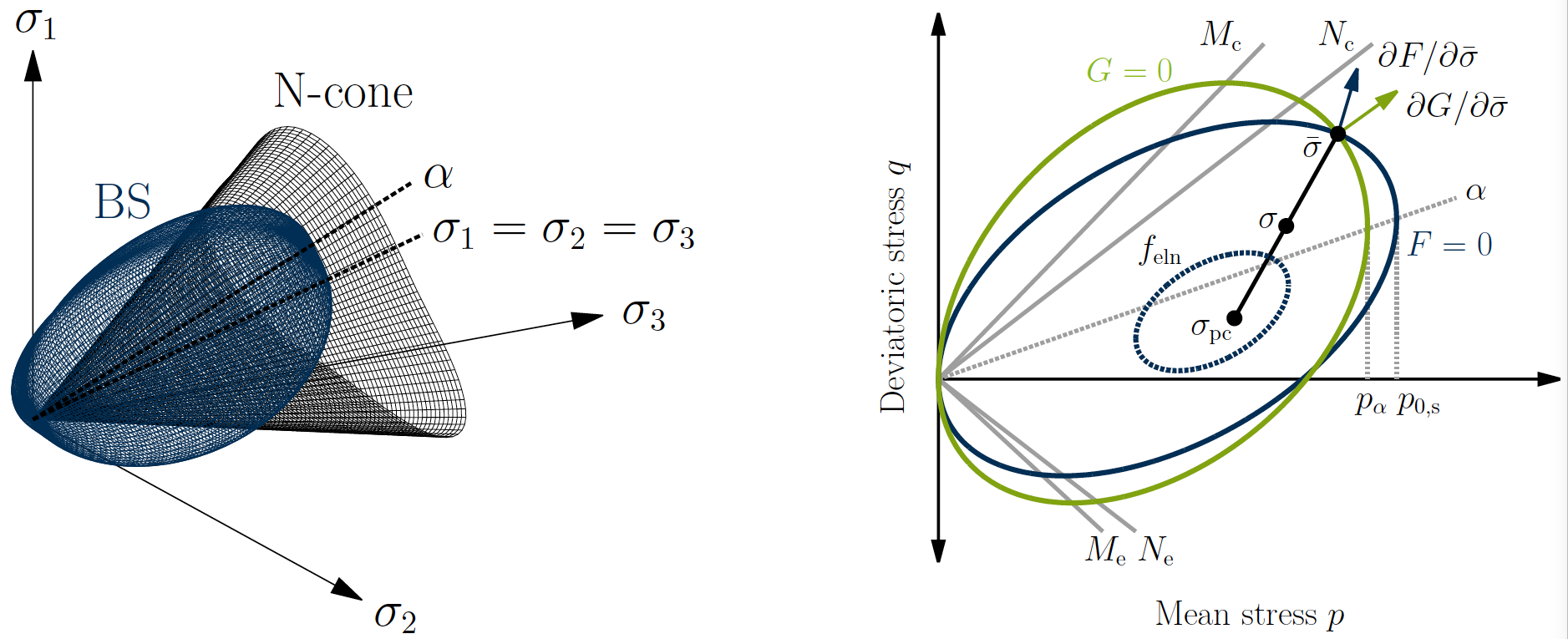

In the previous phases of A5 subproject, we mainly focused on the numerical simulation of mechanized tunnel excavation in dry and fully saturated normally consolidated structured clays. In this frame, constitutive modeling of natural structured soft soil based on bounding surface plasticity, automatic constitutive model adaption, and hydro-mechanical coupled analysis in the near field around the tunnel carried out.

The third phase of A5 subproject aims to study the feasibility of TBM tunneling in swelling soft rocks and to develop an adequate numerical model for mechanized tunnel excavation in over consolidated clay shales with the potential of swelling due to water uptake.

- Considering the details of construction process (e.g., face support, grouting, progressive excavation, etc.) and long term coupled behavior (time dependent coupled TBM-Soft rock-Lining-Grout interaction)

- Hydro-mechanical process of saturated and unsaturated flow around the tunnel and corresponding swelling in shale with consideration of tunneling relevant HM boundary conditions

To be specific, the vapor-water fluid flows in the clay matrix (micro and macro pores), bedding planes and factures will be taken into account. Special attention will be paid to the variation of HM properties of the material in the excavation damage zone (EDZ). Furthermore, the evolution of the swelling pressure with deformation of the grout and lining segments will be investigated for the purpose of optimal lining structural design.